Low Density polyethylene, popularly known as LDPE, is mainly used for packaging and non-packaging applications. This is translucent plastic and is flexible, waterproof chemical resistant, and used primarily to move things from one region to another.

This article will give a detailed description of LDPE and how it is used in the transportation industry extensively.

Characteristics of LDPE

Before falling back to our topic, we should also know the characteristics of LDPE in great detail as that will help understand its applications.

Therefore the characteristics of LDPE can be stated as follows:

- Low material wealth

- High impact strength

- High recyclable capability

- Cheap and easily manufactured

- Flexible, waterproof. Chemical resistant

It is because of these characteristics that the LDPE is not only used in the transportation industry but also in industries like:

– Electrical

– Hydraulics and pneumatics

– Packaging

– Pipes

LDPE more in Details

Other than the little information we have fetched you with, we will also give you a depth of LDPE and LDPE Film in general from the below mentioned points.

- Physical Characteristics- it is a soft film and hence is flexible to a great extent. However, under tremendous stress, there are chances that it may break. It is not entirely transparent, and it is translucent.

- Recyclable- The most advantageous feature of LDPE is indeed the recyclable feature. This feature makes LDPE more environments friendly and, in this climate conscious world of ours, a very suitable product.

- Production Methods- It is produced by compressing monomer ethylene gas in a reactor, and after this process is the linking into polymer chains.

These are the characteristics of LDPE Films and LDPE in detail.

Applications of LDPE in details

LDPE Films are primarily used in several industries, and they can be used in these areas as follows:

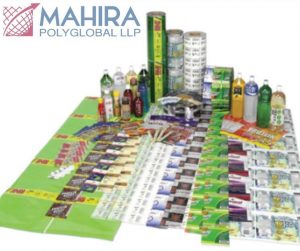

- Packaging Bottles and Films- the films and the plastic bags are all products of the LDPE, and they are also used in food packaging.

- Medical and Healthcare- packaging films, bad headers, containers, etc., are all products of the LDPE.

- Household products and Consumer Goods- any container can be a product of LDPE because the protective lids are also made of this.

- Agriculture- LDPE is widely used for greenhouse, walk-in tunnels, or any other agricultural product.

- Wiring & Cable- Wire insulation and jacketing are all-important contributions of this category.

These are all the different types of uses of the LDPE in various industries other than the transportation industry.

LDPE Films in Transportation Industry

LDPE Films is massively used in the transportation industry, and this includes transit vehicles, RV, Trains, and other types of Vehicles.

In the transportation sector, primarily LPDE Films are used as protective covers and also at times as aesthetic coatings and surfaces in many of the vehicles. They are also used for making the partition between the seats of two passengers.

Other than these, there are also instances where these LPDE films are painted with acrylic and used as a cover for the seats of the transit vehicles.

Since the LPDE sheets are very durable and have high tensile strength, they are also used in RV coatings and for RV appliances.

Since these LPDE are very low on toxicity, the aerospace industry trusts the LPDE havoc, and hence they are used on massive scales in the LPDE industry.

Not only are those, but the interior aircraft components are also covered with these LPDE sheets it is one of the biggest reasons why the use of LPDE sheets is increasing gradually.

Thus we can say that LPDE holds a substantial share in the transportation industry currently and there is a high chance that it will gradually evolve to be a great and monumental product in this industry, keeping HPDE and other polymers behind.

Brief Info

When it comes to polyethylene, then LPDE is the oldest of all among the existing products in the industry. It is used in food and non-food packaging. It has massively been a part of the transportation industry and other industries as well. It is flexible and is heat resistant which makes it so reliable in the eyes of the sectors.

The extrusion coating setting industry of the transport industry is the fulcrum and the catalyst to its growth. The transport industry and this massive growth account for the food industry are like a coating of milk boxes, coating any food products, or layer of juice boxes.

Other than that, injection molding is the extensive and the prime growth sector for LDPE, and as the name suggests, it is used to mold the injections by the LDPE sheets and is used in surgical sectors.

Conclusion

In conclusion, we can say that there are ample LDPE Film Manufacturers as this product has a good market. With the rise in population, we can say that the demand for everything is increasing, and since LDPE is light plastic, it may shine in this climate conscious and sensitive world of ours.