Also known as printed labels or shrink labels, LDPE labels are manufactured with high-level and virgin raw materials to meet all safety purposes. The best known LDPE Labels Manufacturer offers LDPE labels in varying designs, colors, and printing which can have a striking effect on the end product. These labels indirectly help in enhancing the conversation rate, thus widening the path of increasing brand values. These shrink labels effectively provide your brand and its products with a remarkable effect.

Significant features of LDPE labels

- Lightweight

- Moisture and water-resistant

- Cost-effective

- Improved product appearance

- Easy installation

- Resistant to oil, dust, and debris

- Scratch proof

- Striking designs along with finishing

- Different printability options with an innumerable choice of colors

The Usefulness of LDPE Labels

LDPE Labels are heavily used in real-life applications like electric, automobile, pharma, printing, beverage, consumer goods, food, electronic and other industries. With the increased popularity and massive demand, manufacturers prioritize offering LAPE labels in multiple sizes, prints, designs, colors, shapes, and per customer’s needs.

Similar to standard labels, LDPE shrink labels are printed on digital, flexographic, and rotogravure machines. Its extraordinary features like 3d proofing and 36o degree art can be applied to several products simultaneously. These labels are safe, stylish, long-lasting, readily available, and create branding at best. Besides plastic film and polyester, LDPE labels can also be fixed on aluminum cans.

Pros of LDPE labels

- Resistance to chemicals

- Impact toughness

- Low density

Cons of LDPE

- Poor resistance power to heat

- High level of expansion in temperature alteration

- Low-lying strength and stiffness

Different applications of LDPE labels

These are some of the industries where LDPE Labels are widely used:

- Toiletry

- Consumer products

- Food and beverage

- Pharmaceutical

- Stationary

- Packaging and printing

- Cosmetic

- Electrical

- Automobile

- Pesticides

Not only in business, but you can also find low-density polyethylene among different items in your home. These are bags, containers, wash bottles, carton lining, coverings, shrink wrap, pallet wrap, hardware covers, plastic bags, garbage bags, frozen food bags, dry cleaner bags, etc.

How to Recycle LDPE Labels?

To get recycled, plastic film has to be separated. In developed countries, the latest technology helps clean the labeled films before they are transferred to the recycling process. Once the separation is done, LDPE films get crushed in grinders. After becoming flakes, the process cleans out the plastic to eliminate contamination, dirt, and debris. The spotless flakes are dried up, then melted to transform into pellets for easy handling. Now, it’s time to combine the virgin material with the recycled LDPE to originate new products. These reprocessed LDPE can be utilized in manufacturing sheeting, trash bags, and piping films for employment in agriculture, building, and other applications.

Trust One of the Finest LDPE Label Manufacturers

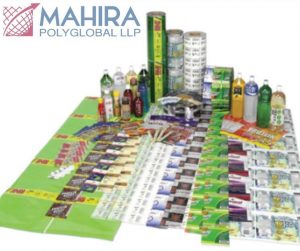

Headquartered in Ahmedabad, Mahira Polyglobal LLP is a famous manufacturing brand of high-level LDPE Labels. The organization offers various labels in attractive designs to improve your brand value and end products. These renowned manufacturers always try their best to produce top-grade LDPE labels for the end clients and meet their unique expectations.