Mahira Poly Global LLP is the superior name in the industry of screw barrel manufacturing and exporting. The company manufactures and exports the highest range of screw barrels, including twin parallel screw barrels, SS & bimetallic screw barrels, twin parallel screw barrels, vented & injection molding screw barrels, and the list goes on! The company also deals with many more products that help smooth the industrial process!

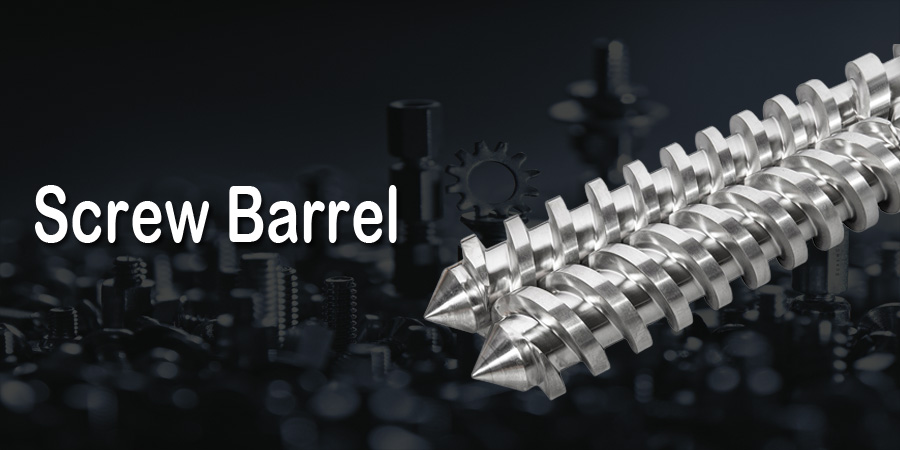

Finding the right screw barrel for the plastic application is challenging. Screw barrel plays an important role in smoothening the industrial production process. The manufacturers of the industrial field are more focused and conscious of the machine’s performance.

Companies are using more and more tools to become more productive and eliminate the hassle between the production lines. This is the major part of the plastic processing machinery where the production process can’t be run successfully without it! This product ensures the engineers deliver the desired output. The company manufactures and designs this tool in the most efficient way with a vast range of diameter options!

What are the special functionalities of this tool?

This screw barrel tool is used in cable wire machinery, food processing, and other small-scale industries. This tool is specially designed to make the production process smoother with better outcomes. The tool is designed with materials with excellent strength, robust structure, and low maintenance! This is highly durable, so multiple industries consider this tool the customizable and standard model.

The company has an in-house professional manufacturer team who regularly tests the screw barrel using modern techniques. This tool plays an essential role in improving the machine’s functionality and increasing productivity and performance. This tool comes to the market loaded with multiple USPs. Mahira Ply Global LLP supplies and delivers the tools with extreme perfection. These extruders screw barrel is popular for delivering better output with less maintenance. Every screw barrel tools exported from the Mahira screw barrel manufacturer are best in wear, abrasion, and corrosion resistance.

The screw barrels are the tools that combine the electronic and mechanical units. This tool is applied almost in every plastic processing machinery. The screws are made with high-quality materials that promote the finishing, durability, and robustness and make it customizable. These tools are used in the blow molding machine, injection molding machine, and plastic extruder machine. This is considered an integral part of the plastics processing industry. Mahira Ply Global has expertise in manufacturing and supplying this product. The manufacturing companies use high-quality Musco materials to manufacture this versatile tool.

How to increase the life cycle of a screw barrel?

If you want to increase the life expectancy of the screw barrel, you need to follow any one of the 2 steps, which include compound purging and removal of parts. The first method is more convenient than the second one, and it also takes a minimum of days to complete. It would be great to ask the engineer which method is best. A person should be conscious while installing the screw barrels. Make sure about the dimensions and extruder alignment.

Check the position and tighten the screw before you have done the job. Mahira Ply Global brings the highest number of screw barrels used in rubber and food industries, granulating machines, sheet extrusion and laminating machines, pellet extruders, and many more! To manufacture this screw barrel, the company uses massive materials containing HDPE, LDPE, PVC, PP, etc., based on the client’s requirement.

The screw barrel design characteristics:

This screw barrel tool is designed with the perfect diameter and length with the right compression ratio. It has better surface finishing with the durable, highest quality construction materials. The manufacturers also focused on the perfect construction materials with surface finishing materials. This screw barrel has 3 major zones with the basic configurations, including a cylindrical feeding zone, metering zone, and conical compression zones. It would be better to bring the screw barrel that delivers resistance to corrosion.

The screw barrels are designed with the 3 different types of wear, ranging from abrasive, corrosive, and adhesive. Different screw barrels made with different types of wear are appropriate for multiple functions. Well, there are so many factors that influence wear, and those are screwed-up design, alignment of the screw, the straightness of the barrel, the reinforcing agents, wear on the screw, corrosion, and the materials used in the screw surface, and others!

Mahira Ply Global LLP contains a massive range of designs and specifications for screw barrels. Anyone can visit and explore the widest section of the screw barrel and purchase one which fits their requirement. This is the trusted and most reviewed platform for buying industrial tools. Improve your productivity and do your job with extra perfection by using the right pair of screw barrels.