The full form of LDPE is Low-Density Polyethene which is made by polymerizing ethylene. Ethylene is usually obtained after cracking a derivative of light petroleum such as naphtha.

The higher pressure process of polymerization is one of the reasons behind its low density. This gives rise to a lot of molecules with several side branches.

LDPE film falls in the category of thermoplastic. After heating the plastic usually softens unlike rubber for instance. This is why it is very suitable for reuse. It can be transformed into other different shapes after the process of heating.

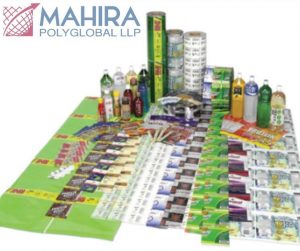

Mahira Polyglobal LLP indulges in the manufacturing of a wide range of LDPE films which is commonly used for plastic film and is very transparent.

How is LDPE film manufactured?

The manufacturing of the film is done with the help of a hi-tech blown film extrusion machine. LDPE plastic film usually comes in contact with different liquid substances but it constitutes no chances of getting wet.

The LDPE film manufacturer keeps in mind that the product is made from virgin material that is free of odour taste. This is why it is considered very safe for packing food products. The production is done with a polymerization process into higher pressure.

How efficient is LDPE film?

The side branches assure that the crystallisation degree remains relatively lower. Because of the irregular shape molecules don’t lie in or even on top of each other in an organised way. Very few of them fit in a particular space.

The lower density of a material depends on the crystallisation degree. One of the most common examples is water and ice. It also possesses incredible electro insulating properties.

The stabilisation of UV can be up to 24 months. The presence of good moisture barrier characteristics along with higher flexibility and corrosive prevention is what makes it more important.

The LDPE film is environmentally friendly and can be recycled easily even after the disposal of the film by either combustion or landfill but it is assured that any kind of harmful substance won’t be released by it which can harm the environment.

What are the characteristics and applications of LDPE film?

LDPE film serves its best purpose in a variety of applications such as bread bags, grocery bags, beverages, shipping bags, sports goods, gift wrapping, clothes wrapping, gift wrapping, magazines, shrink film, bags, transport wrapping as well as insert printing etc.

Some of the characteristics are as follows:-

- Excellent clarity

- Resistant to heat and puncture

- Flexibility

- Quality Finish

- Reasonable cost

- Resistant to chemicals

- Conductive

- Anti-static

It is used for laminating different products as well as packaging different items. It is also available in the form of a roll. All the products are properly tested by highly skilled and experienced professionals.

What are some of the advantages of LDPE film?

LDPE comes in the category of one of the toughest plastics which constitute multiple side branches in the molecular structure that it’s soft yet quite strong. Moreover, it is very water-repellent, resistant to acids as well as insulating.

Hence it is suitable for packaging material. The film might come in contact with food and is widely used in the food industry. It is ideal for shrink films because of its molecular structure. Every kind of PE shrinks after heating it in the longitudinal direction of your film.

The film is capable of shrinking properly in the width directions because of the side branches. One of the primary benefits of LDPE is that little material is required for packaging.

This proves the fact that very little energy is required for the production process. Meanwhile, the production of lesser CO2 emissions is done in comparison to other packaging materials due to its lightweight as well as little volume.

Conclusion:-

LDPE films are not suitable for those applications where higher structural strength, stiffness as well as high-temperature resistance is required.

It is commonly used for both prosthetics as well as orthotics. Since it has higher resistance from chemicals it can be easily fabricated.

They provide excellent protection from corrosion and weathering. It also offers a wide range of thermoplastic coatings with a lot of performance characteristics.